Operational Advantages ofBlastwall Fiberglass

Blastwall fiberglass deflector fence provides many key advantages over traditional airport wall structures made of steel:

• NO RUNWAY CLOSURES: Installation is by work crews without need for cranes that will block access to landing paths.

• NO CORROSION: The all-fiberglass structure, plating, girders and bolts offer virtually an indefinite operational lifetime with almost zero maitenance over many years.

• ZERO RADAR FOOTPRINT: The performance of ground radar and radio beacons is not affected since Blastwall's frame and plating contain no steel components.

• MINIMUM SITE PREPARATION: Leveling and placement of concrete mounting points with steel bolts at ground level is the only site preparation required.

• WE ALSO SUPPLY STEEL WALLS: When the above performance factors are not relevant to your site requirements, we can also custom design and manufacture traditional all-steel blast deflector walls. Please see further details regarding Blastwall Steel on the engineering page.

• MOVABLE BLASTWALL OPTION: We are also innovators for movable jet blast walls in unique circumstances where repositionable blast protection is needed. Contact us for details about this new Blastwall feature.

Photographs of Blastwall FiberglassComponent Details

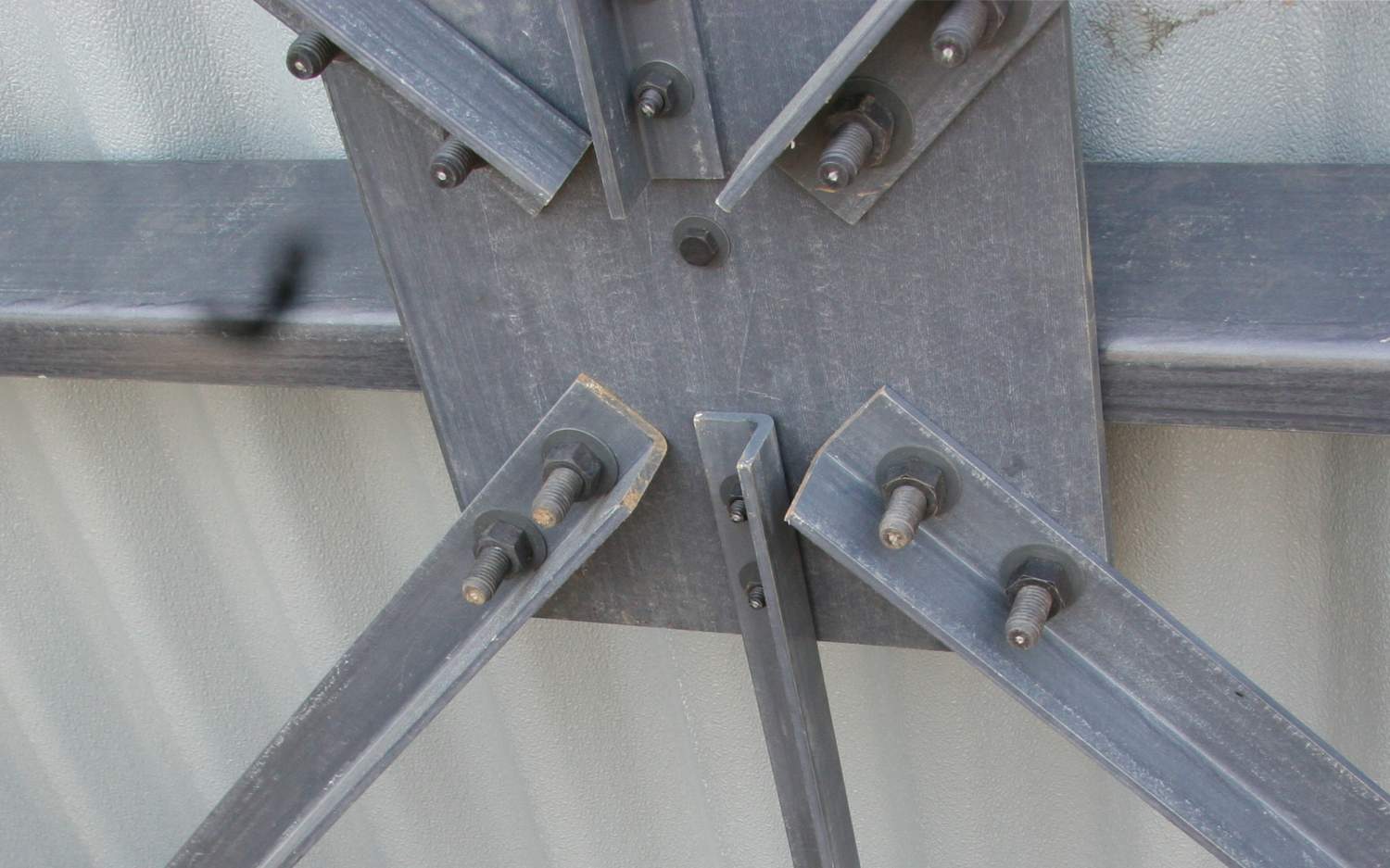

As these detailed photographs illustrate, all the panels, girders, struts, bolts and nuts in a Blastwall installation are made of fiberglass and therefore are invisible to radar.

• Advance the photos manually by clicking on the arrow buttons at left/right edges of images.

• Buttons for full-screen or large-format viewing are at bottom-right of frame.

• Autoplay pause/resume button is at bottom-left of frame.

Blastwall PerformanceFeatures

- Available in steel or fiberglass, custom-designed to your precise site specifications.

- Non-conductive and non-magnetic to radar and radio frequencies.

- Engineered to withstand jet takeoff blast and associated high temperatures.

- Frangibility in the event of impact by aircraft achieved through specially engineered shear points.

- Structurally lightweight and easy to set without the need for cranes.

- No service interruption during installation.

- Fire-retardant, Class 1 flame-spreading rating 25 or less per ASTM E84.

- Pigment and UV stabilizers incorporated into the resin making it corrosion and UV resistant.

- Self-cleaning and maintenance free.

- Tested by NAV Canada for non-interference performance during ground based and in-flight electronic signal emissions.

- Movable or repositionable wall design options are available.

- Also accepted by the FAA for installation in the United States.

- Meets or exceeds NAV Canada regulations for airside installation.