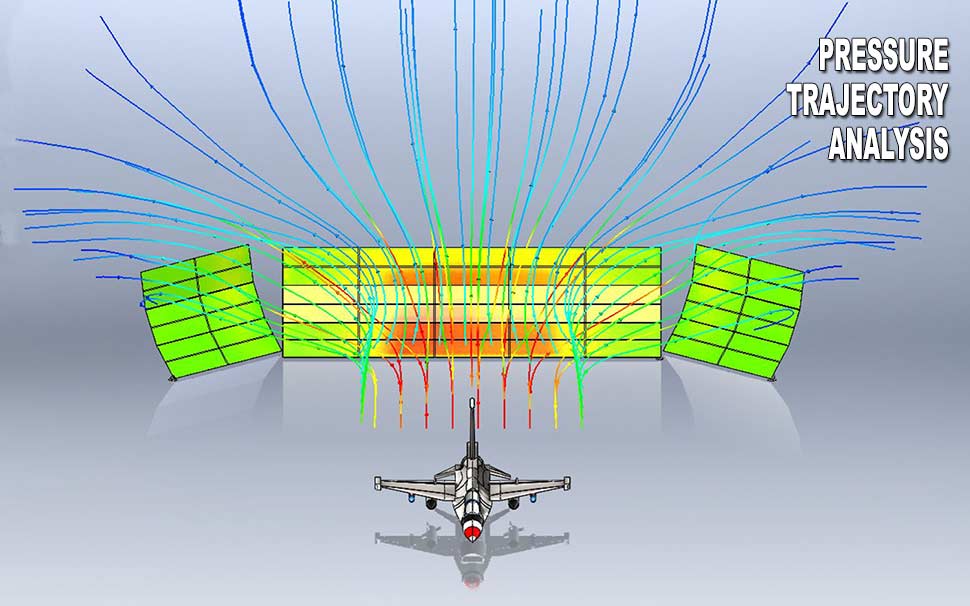

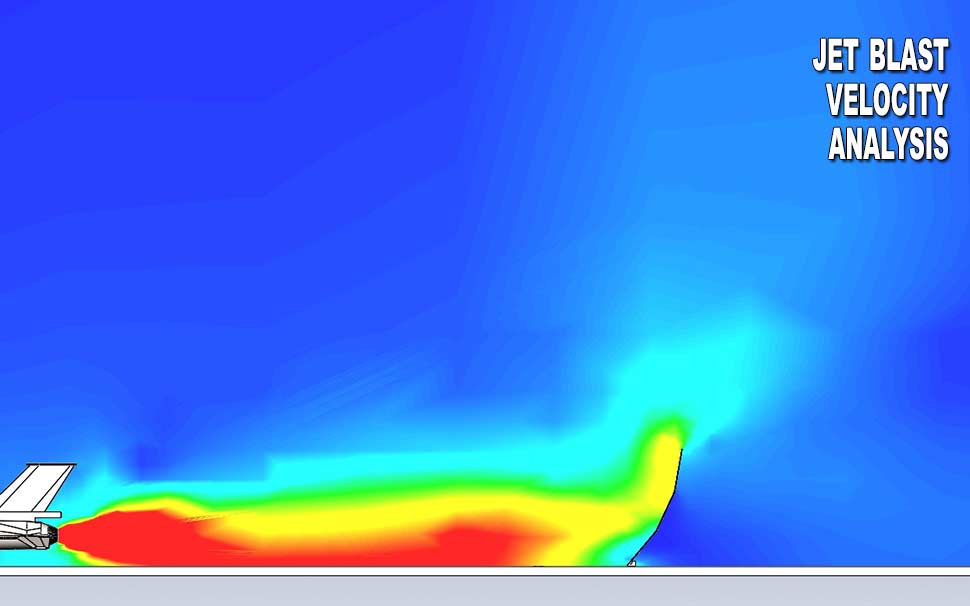

Blastwall Engineering & Design AnalysisSteel or Fiberglass

Blastwall has a variety of standard walls, made of steel or radar-invisible fiberglass, for the protection of buildings, navigation equipment, vehicle traffic and ground personnel. Blastwall also has the capability to custom design a jet blast protection wall to your airport's unique requirements, including movable or repositionable blast protection walls.

Determining the type of wall required starts with the basics: the purpose of the protection, the location, the aircraft using the facility, whether frangibility is needed, the distance between the aircraft and the wall and the budget. There can be other customization factors, so we invite you to contact and consult with Blastwall about your specific needs.

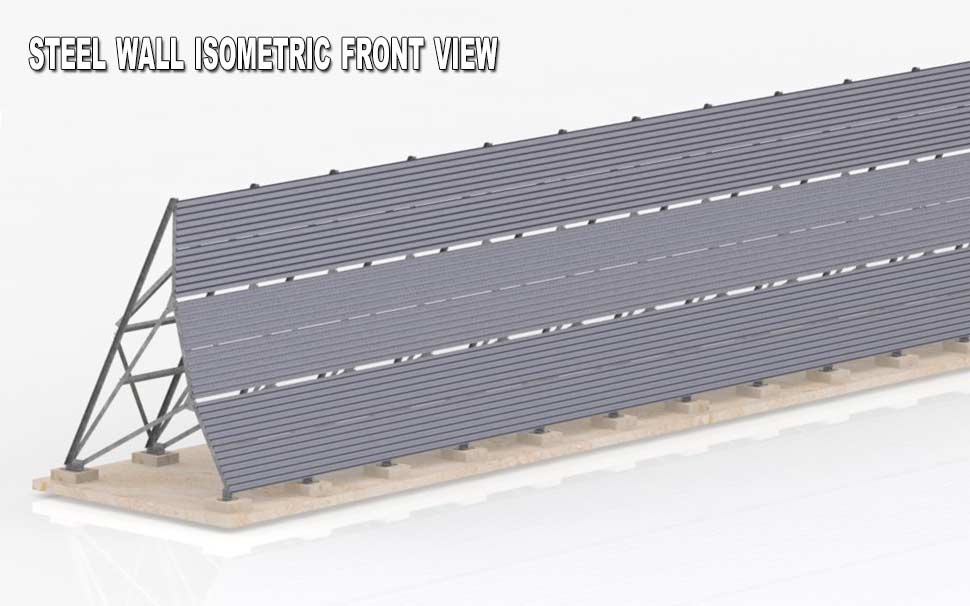

Blastwall Steel

Steel is the economical solution when frangibility or radar invisibility are not required, but protection is still needed for buildings, vehicles or personnel. Blastwall steel walls are custom designed to your site specifications and manufactured from cost-saving galvanized steel.

BENEFITS OF BLASTWALL STEEL WALLS:

• Designed with high safety margins and to a variety of design strengths depending on their application;

• Cost saving design and materials;

• Minimum site preparation - Levelling of ground for the wall footprint and placement of concrete mounting points with steel bolts.

• Read the specifications and performance features for our steel jet blast protection walls.

Blastwall Fiberglass

Blastwall's patented fiberglass walls are invisible to radar and radio transmissions. Our fiberglass walls can be built to custom heights and custom footprint widths. They can be made frangible to collapse on impact, or rigid and strong, while still remaining invisible. Blastwall fiberglass walls are the ideal solution when it's vital "not to see it".

BENEFITS OF BLASTWALL FIBERGLASS WALLS:

• Patented all-fiberglass construction for zero-radar footprint;

• Can be of a frangible design so that in the event of impact by an aircraft, the wall breaks at specially engineered shear points, minimizing damage to aircraft;

• Corrosion-resistant and maintenance-free materials;

• Easy installation, no runway closures and no cranes are needed;

• Minimum site preparation: level ground for the fence footprint and place steel bolts in concrete as mounting points.

• Read the specifications and performance features for our fiberglass jet blast protection walls.